The project will be using a 1999 Ford Crown Victoria Police Interceptor. This car was selected because it is a sturdy and reliable car with around 230 horsepower (your average import sedan has around 100 to 120 hp). This is a big car with a big 8 cylinder engine. It is a gas hog and gets about 15-22 mpg depending on how it's driven. When a wood gas module is added to this car it will have roughly a 45% decrease in horsepower, meaning it will make about 130hp on wood. The efficiency of the engine will increase by 37% meaning that the miles per gallon (mpg) equivalent on wood power meaning it will get 21-30 mpg. It requires roughly 10 to 16 pounds of wood to equal one gallon of gasoline.

|

| Here is the car in question, a 1999 police car, I think it was NJ highway patrol. I named him Wilfred. |

Now that you've heard some of the numbers here is some information on what I've done so far. I have begun to rip the floor covering out of the car due to a need to run wires and also install a console where all the controls will be located. The cigarette lighter has been cut off and the wires are ready to be connected to various electronic devices and lights that will be on the control panel.

|

| This is where the console will be put soon. The wire sticking out with the blue tape on it is where the cigarette lighter used to be connected |

When you convert a car to wood power it is also essential to turn off all of the systems that supply gasoline to the engine. This is mainly the fuel pump, which moves fuel to the front of the car, and the fuel injectors, which squirt fuel mist into the engine. The fuel pump shutoff was easy to do because there was a fuel pump emergency shutoff switch already in place in the trunk. This was cut and removed from the car and a toggle switch was wired in temporarily. Soon there will be wires connected so that the fuel pump can be shut off by the driver, and there will also be a dimmer switch installed, which basically acts like a water faucet, the fuel flow will slowly be turned lower and lower until it stops flowing with this switch. The reason this is important is because gasoline is used to start the car but once the wood gasifier is running strong, the engine is gently switched over from gasoline to wood gas.

|

| Here is the fuel pump shutoff switch installed where the emergency shutoff switch used to be, this is in the trunk of the car. Longer wires will be installed so the driver can operate the switch soon. |

The other system that was installed is the fuel injector shutoff system. This is important because the fuel injectors (the devices that put fuel into the engine) should not be running without gasoline. Because they are electronic they would continue to move even without gasoline if a shutoff switch was not installed. This system took about 5 hours to install. It was a scary moment when I cut all of the wires on my engine, I knew there was no turning back! In the end though everything went smoothly and the system works really well without a hitch.

|

| Here is the toggle switch that can turn on and off all 8 fuel injectors. |

|

| here is a picture of the new connection that I added to the existing wiring so I could control the fuel injectors. (the yellow thing is a fuel injector) |

|

| This is one side of the fuel injector shutoff system. You can tell where it is because it is shinier than the dirty engine (which will be getting a good cleaning very soon). Note that the wire bundle has been protected with some fresh corrugated tubing |

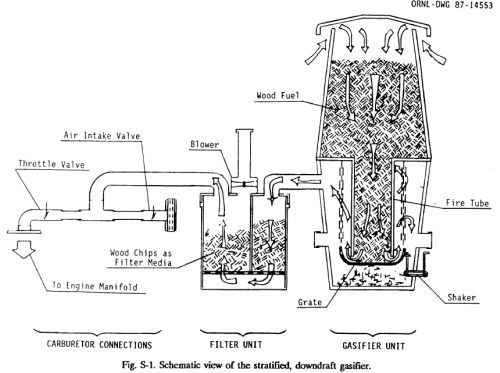

I just want to say thanks in advance to Mr. Wayne Keith who is an innovator and thinker and a pioneer in modern wood gas. I admire his techniques greatly. I don't want anyone to think that the gasifier I am building for this car is my idea. The gasifier design is a very old idea that Mr. Keith has improved significantly so that somewhat modern vehicles can travel at highway speeds on wood. What I will be doing is creating computerized systems to monitor and control everything within the wood powered car. The gasifier is Mr. Keith's design, the controls will be my own design. If you are considering building a wood powered truck or car please visit

http://driveonwood.com/ and think about purchasing Wayne Keith's book Have Wood Will Travel. It is an excellent read and an essential part of my own build.